Facilities at Foundry Division (Unit I ) Navage:-

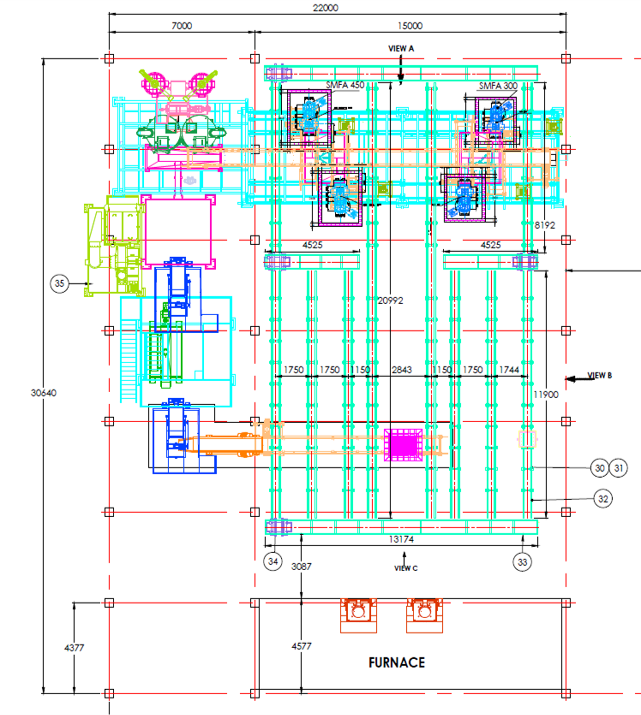

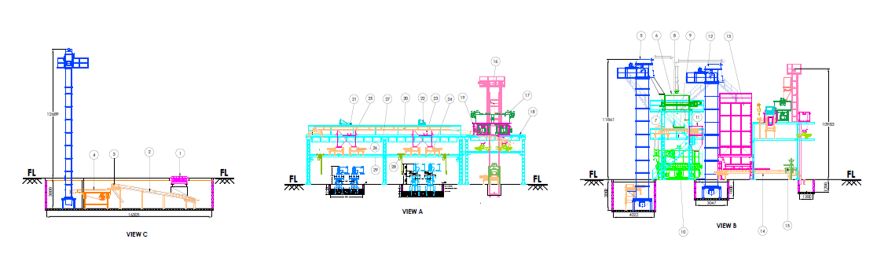

- Molding Process : Full automized HPML line for Green Sand plant of20 Mt per hour capacity.

- Molding Method : 28 X 26 Fix box line, High Pressure molding line.

- Core Process : Shell , Sodium Silicate CO2, No-Bake, Cold box.

- Production Capacity : 450 MT per Month

- Range of the Castings : 15.00 Kg to 55.000 Kgs

- Grades : All grades of S.G. Iron and Gray Iron.

- Melting : 550 KW Panel with 500 Kg Pot 2- nos.

- Surface Finish : Hanger type Shot Blast, Table type shot blastmachine & Sand Blast machine

Facilities at Foundry Division (Unit II ) Udyambag:-

- Production Capacity : 100 MT per Month.

- Range of the Castings : 0.500 Kg to 300.000 Kgs

- Grades : All grades of S.G. Iron and Gray Iron.

- Molding Process : Shell Mold, CO2 , And No-Bake.

- Molding Method : Shell Stack molding, Fix box hand molding.

- Core Process : Shell , Sodium Silicate CO2, No-Bake, Cold box.

- Melting : 350 KW Panel with 300 Kg Pot 1- nos.

- Surface Finish : Table type shot blast Machine

- Pattern : Out Source